+44 (0)121 537 4525 sales@lineboringandwelding.com

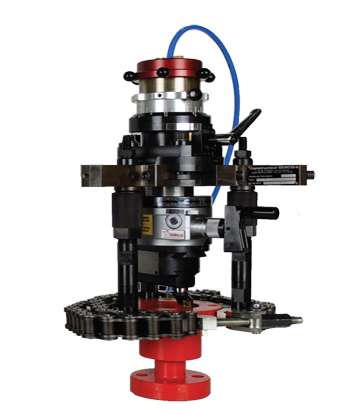

| In Line Boring Also Blind Holes: | From ∅ 30mm To ∅ 2500mm Standard |

| Internal Welding Also Blind Holes: | From ∅ 30mm To ∅ 250mm Standard |

| External Welding Also Blind Holes: | From ∅ 30mm To ∅ 250mm Standard |

| Drilling: | See Optional Accessory Kits |

| Tapping: | See Optional Accessory Kits |

| Stroke: | 350mm Continuous Traverse |

| Transmission: | 2/1 Helical Transmission Gearbox |

| Output Torque @ Bar 1° Gear: | 536.5NM |

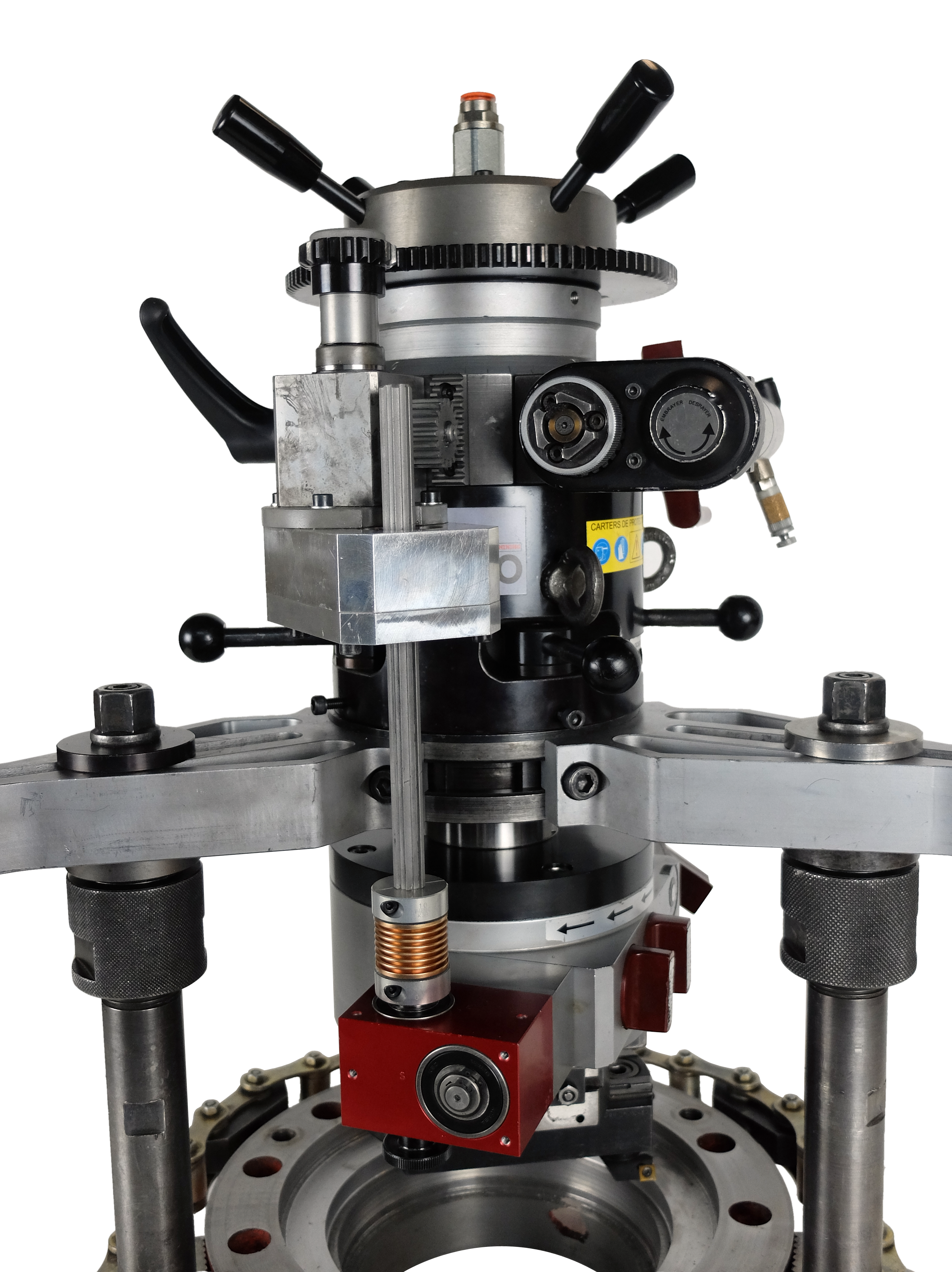

| In Line Boring Also Blind Holes: | From ∅ 40mm To ∅ 250mm Standard |

| Internal Welding Also Blind Holes: | From ∅ 40mm To ∅ 250mm Standard |

| External Welding Also Blind Holes: | From ∅ 40mm To ∅ 250mm Standard |

| Drilling: | From ∅ 10 To ∅ 45mm |

| Tapping: | From ∅ 10 To ∅ 45mm |

| Stroke: | 250mm Continuous Traverse |

| Transmission: | 2/1 Helical Transmission Gearbox |

| Output Torque @ Bar 1° Gear: | 536.5NM |

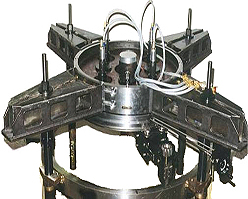

| In Line Boring Also Blind Holes: | From ∅ 40mm To ∅ 400mm Standard |

| Internal Welding Also Blind Holes: | From ∅ 40mm To ∅ 400mm Standard |

| External Welding Also Blind Holes: | From ∅ 40mm To ∅ 400mm Standard |

| Drilling: | From ∅ 10 To ∅ 45mm |

| Tapping: | From ∅ 10 To ∅ 45mm |

| Stroke: | 350mm Continuous Traverse |

| Transmission: | 4/1 Helical Transmission Gearbox |

| Output Torque @ Bar 1° Gear: | 1145.39NM |

| In Line Boring Also Blind Holes: | From ∅ 60mm To ∅ 600mm Standard |

| Internal Welding Also Blind Holes: | From ∅ 60mm To ∅ 600mm Standard |

| External Welding Also Blind Holes: | From ∅ 60mm To ∅ 600mm Standard |

| Drilling: | See Optional Accessory Kits |

| Tapping: | See Optional Accessory Kits |

| Stroke: | 350mm Continuous Traverse |

| Transmission: | 4/1 Helical Transmission Gearbox |

| Output Torque @ Bar 1° Gear: | 1145.39NM |

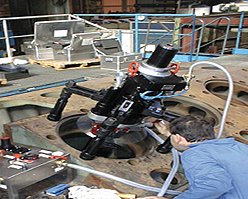

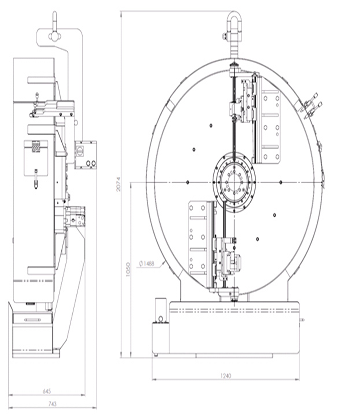

| In Line Boring Also Blind Holes: | From ∅ 60mm To ∅ 800mm Standard |

| Internal Welding Also Blind Holes: | From ∅ 40mm To ∅ 800mm Standard |

| External Welding Also Blind Holes: | From ∅ 40mm To ∅ 800mm Standard |

| Drilling: | See Optional Accessory Kits |

| Tapping: | See Optional Accessory Kits |

| Stroke: | 350mm Continuous Traverse |

| Transmission: | 4/1 Helical Transmission Gearbox |

| Output Torque @ Bar 1° Gear: | 1464.21NM |

| Model | Part No. | Diameters | Description |

| SC1 | KEP00187 | ∅ 22mm to ∅ 50mm | Line Boring Reduction Kit for small bores |

| SC1 | KEP00188 | ∅ 32mm to ∅ 100mm | Line Boring Reduction Kit for small bores |

| SC2/SC3 | KEP00594 | ∅ 22mm to ∅ 50mm | Line Boring Reduction Kit for small bores |

| SC2/SC3 | KEP00593 | ∅ 22mm to ∅ 100mm | Line Boring Reduction Kit for small bores |

| SC2/SC3 | KEP00678 | ∅ 42mm to ∅ 140mm | Line Boring Reduction Kit for small bores |

| Model | Part No. | Diameters | Description |

| SC1 | KED00180 | ∅ 400mm to ∅ 600mm | Line Boring & Rotary Welding Kit for large bores |

| SC2 | KED00360 | ∅ 600mm to ∅ 800mm | Line Boring & Rotary Welding Kit for large bores |

| SC2 | KED00366 | ∅ 600mm to ∅ 1200mm | Line Boring Reduction Kit for small bores |

| SC3 | KED00365 | ∅ 800mm to ∅ 1200mm | Line Boring Reduction Kit for small bores |

| Model | Part No. | Diameters | Description |

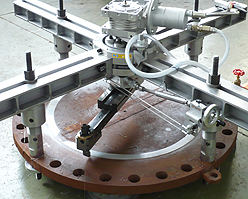

| All Models | KES00186 | ∅ 65mm to ∅ 160mm | Flange Facing Kit for boss faces etc |

| All Models | KES00189 | ∅ 65mm to ∅ 260mm | Flange Facing Kit for boss faces etc |

| All Models | KES00200 | ∅ 80mm to ∅ 240mm | Flange Facing Kit for boss faces etc |

| All Models | KES00201 | ∅ 80mm to ∅ 400mm | Flange Facing Kit for boss faces etc |

| All Models | KES30023 | ∅ 80mm to ∅ 160mm | Circlip Groove Kit |

| All Models | KES30024 | ∅ 100mm to ∅ 250mm | Circlip Groove Kit |

| SC2/SC3 | KES00363 | ∅ 250mm to ∅ 500mm | Flange Facing Kit for boss faces etc |

| SC2/SC3 | KES00364 | ∅ 400mm to ∅ 800mm | Flange Facing Kit for boss faces etc |

| Model | Part No. | Diameters | Description |

| All Models | KEL00185 | ∅ 100mm to ∅ 300mm | Kit for External Machining & Welding |

| All Models | KEL00202 | ∅ 150mm to ∅ 400mm | Kit for External Machining & Welding |

| Model | Part No. | Diameters | Description |

| All Models | AE000643 | N/A | Digital CNC Control Panel, with programmable feed limit lengths and automatic retraction |

| SC1 | AE000487 | ∅ 40mm | Boring Bar Connection Joint (a) |

| SC1 | AE000488 | ∅ 40mm | Boring Bar Connection Joint (b) |

| SC2 | AE000441 | ∅ 60mm | Boring Bar Connection Joint (a) |

| SC2 | AE000442 | ∅ 60mm | Boring Bar Connection Joint (b) |

| All Models | AE030015 | N/A | Step Welding Cam System. A welding cam system for automatic to stop and start intervals |

| SC1 | AE003018 | ∅ 40mm to ∅ 1500mm | Boring Bar 40mm x 1500mm |

| SC1 | AE003017 | ∅ 40mm to ∅ 3000mm | Boring Bar 40mm x 3000mm |

| SC2/SC3 | AE001027 | ∅ 60mm to ∅ 1500mm | Boring Bar 60mm x 1500mm |

| SC2/SC3 | AE030025 | ∅ 60mm to ∅ 3000mm | Boring Bar 60mm x 1100mm with Morse Tapper No. 4 |

| SC2/SC3 | AE003014 | ∅ 60mm to ∅ 3000mm | Boring Bar 60mm x 3000mm |

| All Models | KFL00928 | ∅ 120mm to ∅ 350mm | Threading Kit. Please call for Bespoke diameters. |

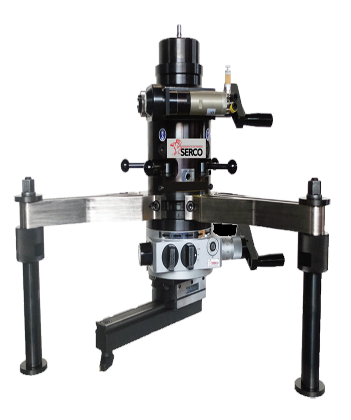

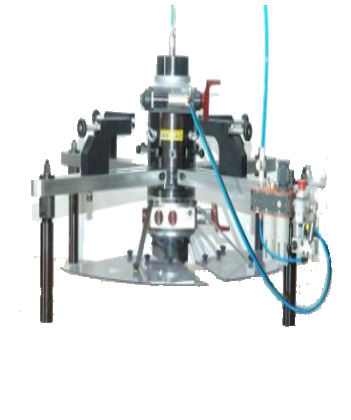

| Machining Ø (mm): | Ø 0 – 200mm |

| Clamping: | Ø 100 – 290mm |

| Axial Stroke: | 70mm |

| Radial Stroke: | 30mm |

| Pneumatic Motors (Bar 6): | 150 W |

| Working Air Pressure (Bar): | 5 - 7 |

| Air COnsumption (L/Min): | 350 |

| Weight: | 15 |

| Dimensions: | 410 x 310 x 370mm |

| Weight with Machine & Components: | 30KG |

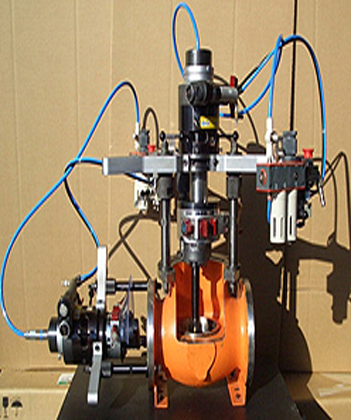

| Machining Ø (mm): | Ø 0 – 400mm |

| Clamping: | Ø 220 – 430mm |

| Axial Stroke: | 100mm |

| Axial Auto-Feed (mm/min): | 0 - 24 |

| Radial Stroke: | 40mm |

| Radial Auto-Feed (2 Speeds): | 0.05 / 0.15mm per Rev |

| Automatic Rapid Return: | 0.4mm/Rev |

| Pneumatic Motor (Bar 6): | 780 W |

| Axial Feed Motor: | 150 W |

| Working Air Pressure (Bar): | 5 - 7 |

| Air Consumption (L/Min): | 1500 |

| Weight: | 35KG |

| Dimensions: | 680 x 530 x 380mm |

| Weight with Machine & Components: | 65KG |

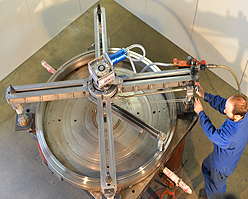

| Machining Ø (mm): | Ø 0 – 600mm |

| Clamping: | Ø 250 – 720mm |

| Axial Stroke: | 130mm |

| Axial Auto-Feed (mm/min): | 0 - 24 |

| Radial Stroke: | 60mm |

| Radial Auto-Feed (2 Speeds): | 0.05 / 0.15mm per Rev |

| Autmoatic Rapid Return: | 1mm/Rev |

| Pneumatic Motor (Bar 6): | 780 W |

| Axial Feed Motor: | 150 W |

| Working Air Pressure (Bar): | 5 - 7 |

| Air Consumption (L/Min): | 1500 |

| Weight: | 65KG |

| Container 1 Dimensions: | 680 x 530 x 380mm |

| Container 1 Weight with Machine & Fixing Arms: | 75KG |

| Container 2 Dimensions: | 680 x 530 x 380mm |

| Container 2 Weight with Columns & Components: | 48KG |

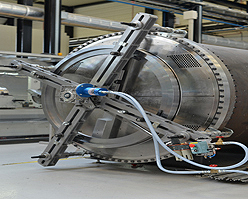

| Machining Ø (mm): | Ø 0 – 1100mm |

| Clamping: | Ø 280 – 1210mm |

| Axial Stroke: | 150mm |

| Axial Auto-Feed (mm/min): | 0 - 24 |

| Radial Stroke: | 100mm |

| Radial Auto-Feed (2 Speeds): | 0.062 / 0.186mm per Rev |

| Autmoatic Rapid Return: | 1.24mm/Rev |

| Pneumatic Motor (Bar 6): | 570 W |

| Axial Feed Motor: | 150 W |

| Working Air Pressure (Bar): | 5 - 7 |

| Air Consumption (L/Min): | 1450 |

| Weight: | 120KG |

| Container 1 Dimensions: | 700 x 500 x 540mm |

| Container 1 Weight with Machine & Fixing Arms: | 145KG |

| Container 2 Dimensions: | 700 x 500 x 540mm |

| Container 2 Weight with Columns & Components: | 155KG |

| Machining Ø (mm): | Ø 0 – 1200mm |

| Clamping: | Ø 280 – 1310mm |

| Axial Stroke: | 150mm |

| Axial Auto-Feed (mm/min): | 0 - 24 |

| Radial Stroke: | 100mm |

| Radial Auto-Feed (2 Speeds): | 0.062 / 0.186mm per Rev |

| Autmoatic Rapid Return: | 1.24mm/Rev |

| Pneumatic Motor (Bar 6): | 570 W |

| Axial Feed Motor: | 150 W |

| Working Air Pressure (Bar): | 5 - 7 |

| Air Consumption (L/Min): | 1450 |

| Weight: | 140KG |

| Container 1 Dimensions: | 700 x 500 x 540mm |

| Container 1 Weight with Machine & Fixing Arms: | 160KG |

| Container 2 Dimensions: | 700 x 500 x 540mm |

| Container 2 Weight with Columns & Components: | 155KG |

| Facing Ø (mm): | Ø 0 – 600mm |

| Clamping: | Ø 200 – 660mm |

| Radial Stroke: | 40mm |

| Radial Auto-Feed (2 Speeds): | 0.05 / 0.15mm/Round |

| Stroke of Cutting Tool: | 15mm |

| Drive Motor: | 340 W |

| Drive Motor Speed: | 100 RPM |

| Working Air Pressure (Bar): | 5 - 7 |

| Air Consumption (L/Min): | 1500 |

| Height: | 150mm |

| Weight: | 25KG |

| Facing Ø (mm): | Ø 0 – 1200mm |

| Clamping: | Ø 500 – 140mm |

| Radial Stroke: | 100mm |

| Radial Auto-Feed (2 Speeds): | 0.062 / 0.186mm/Round |

| Automatic Rapid Return: | 1.24mm/Rev |

| Stroke of Cutting Tool: | 50mm |

| Drive Motor: | 2KW / 6 Bar |

| Drive Motor Speed: | 45 RPM |

| Working Air Pressure (Bar): | 6 |

| Air Consumption (L/Min): | 2500 |

| Height: | 350mm |

| Weight: | 220KG |

| Facing Ø (mm): | Ø 0 – 1800mm |

| Clamping: | Ø 500 – 2050mm |

| Radial Stroke: | 100mm |

| Radial Auto-Feed (2 Speeds): | 0.062 / 0.186mm/Round |

| Automatic Rapid Return: | 1.24mm/Rev |

| Stroke of Cutting Tool: | 50mm |

| Drive Motor: | 2KW / 6 Bar |

| Drive Motor Speed: | 45 RPM |

| Working Air Pressure (Bar): | 6 |

| Air Consumption (L/Min): | 2500 |

| Height: | 550mm |

| Weight: | 310KG or 450KG |

| Facing Ø (mm): | Ø 0 – 2080mm |

| Clamping: | Ø 1300 – 2350mm |

| Radial Stroke: | 560mm |

| Radial Auto-Feed (2 Speeds): | 0.1 / 1mm per Rev |

| Stroke of Cutting Tool: | 50mm |

| Drive Motor: | 3KW / 6 Bar |

| Drive Motor Speed: | 45 RPM |

| Working Air Pressure (Bar): | 6 |

| Air Consumption (L/Min): | 3500 |

| Height: | 630mm |

| Weight: | 250KG or 600KG |

| Facing Ø (mm): | Ø 0 – 600mm |

| Clamping: | Ø 240 – 680mm |

| Axial Stroke: | 32mm |

| Axial Feed: | Manual |

| Radial Stroke: | 40mm |

| Radial Auto-Feed (2 Speeds): | 0.05 / 0.15mm |

| Max Power of Spindle Motors (2 Reversible, Pnuematic Motors): | 2 x 740W |

| Driving Motor Maxi Free Speed: | 140mm |

| Working Air Pressure (Bar): | 5 - 7 |

| Air Consumption (L/Min): | 1500 - 200 |

| Height: | 300mm |

| Weight (without Columns): | 65KG |

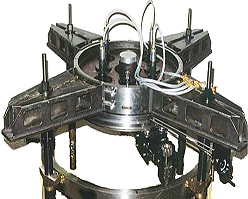

| Facing Ø (mm): | Ø 1000 – 2300mm |

| Clamping: | Ø 1250 – 2500mm |

| Axial Stroke: | 50mm |

| Axial Feed: | 0.08mm per Rev |

| Radial Stroke: | 100mm |

| Radial Auto-Feed (2 Speeds): | 0.062 / 0.186mm per Rev |

| Pneumatic Motors: | 4 x 900W |

| Air Pressure (L/Min): | 5000 |

| Weight: | 1600KG |

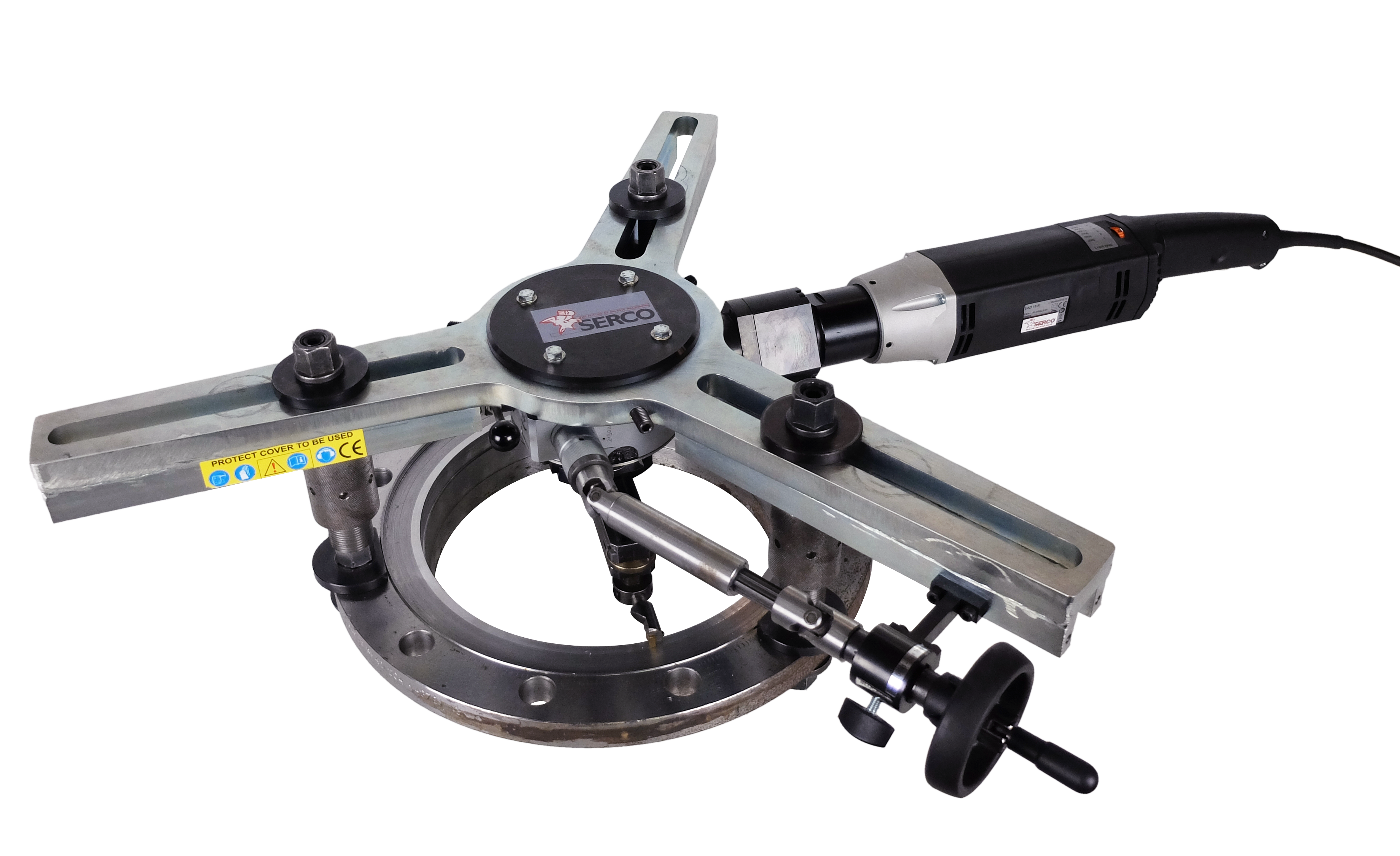

| Boring Diameter: | Ø 400mm |

| Radial Stroke: | 40mm |

| Adaptable Plate |

| Boring Diameter: | Ø 360 TO Ø 600mm |

| Radial Stroke: | 60mm |

| Adaptable Plate |

| Boring Diameter: | Ø 400 TO Ø 900mm |

| Radial Stroke: | 100mm |

| Adaptable Plate, with 4 special columns for fixing, and 1 set of 4 longer arms allowing clamping on diameters from 350mm to 1210mm |

| Boring Diameter: | Ø 400mm |

| Radial Stroke: | 40mm |

| Adaptable Plate |

| Boring Diameter: | Ø 360 TO Ø 600mm |

| Radial Stroke: | 60mm |

| Adaptable Plate |

| Boring Diameter: | Ø 400 TO Ø 900mm |

| Radial Stroke: | 100mm |

| Adaptable Plate, with 4 special columns for fixing, and 1 set of 4 longer arms allowing clamping on diameters from 350mm to 1210mm |

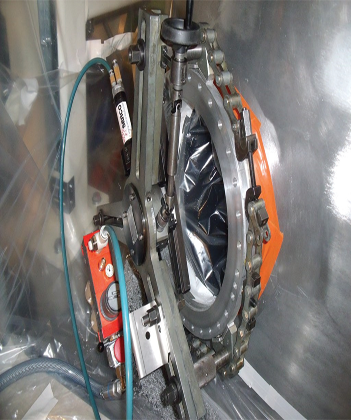

| Angular Accuracy: | - |

| Machining Accuracy: | 0.01mm |

| Roughness | Ra 1.6 |

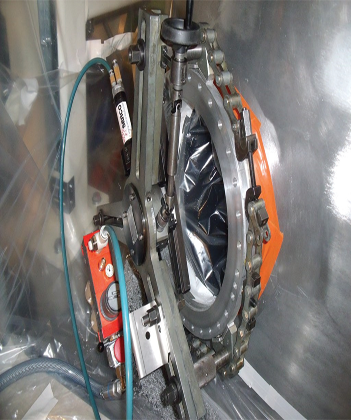

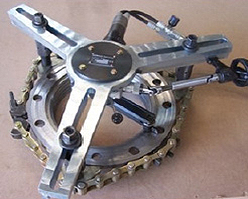

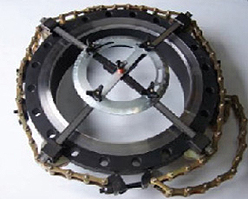

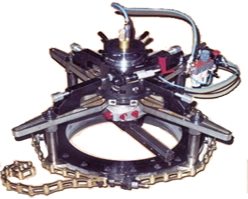

| Clamping Diameter: | Ø 160 – 745mm |

| Minimum Thickness of the Flange: | 20mm |

| Chain Adjustment | |

| Jaws Angular |

| Clamping Diameter: | Ø 430 – 1150mm |

| Minimum Thickness of the Flange: | 30mm |

| Chain Adjustment | - |

| Jaws Angular | - |

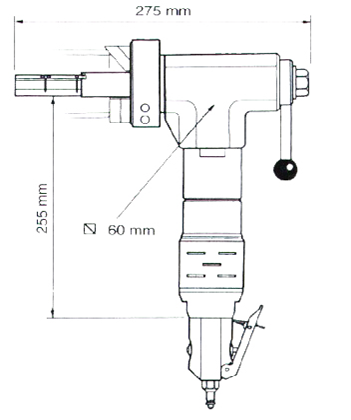

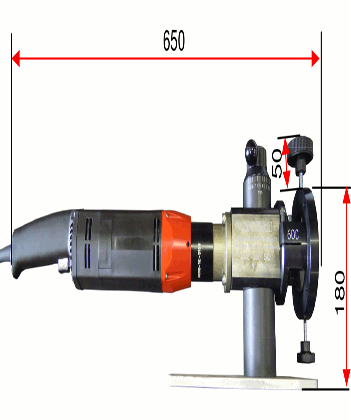

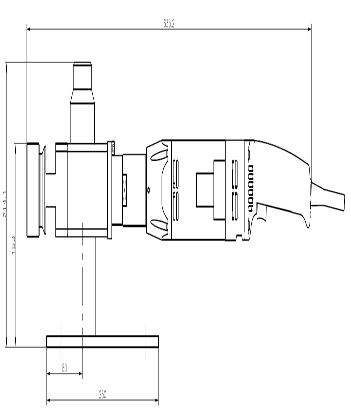

| Remachining Diameter: | 200mm (+TU 400) |

| Remachining Depth: | 180mm (+TU 400) |

| Revolution Speed (Free Speed): | 30,000 rpm |

| Power: | 220W |

| Weight: | 0.9 KG |

| Air Consumption (L/Min): | 340 |

| AC 38 + TU400 - TA240 - TA120: | Ø 100 – 320mm |

| AC 38 + TU600 - TA240 - TA170: | Ø 150 – 580mm |

| AC 38 + TU1100 - TA240 - TA220: | Ø 200 – 1000mm |

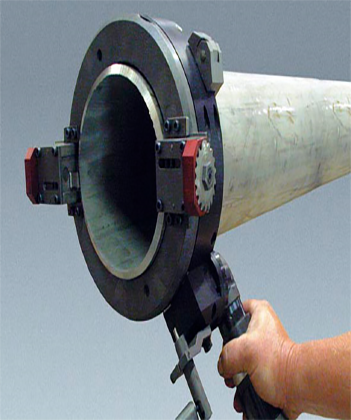

| Machining Capicity: | 25mm ID – 90 mm OD - With Optional Kit 12.5 mm ID – 120 mm OD |

| Bevel Shapes & Angles: | I, V, U, X, Compound Bevels, Other Shapes on Request |

| Clamping: | Manual with Key |

| Feed Stroke: | 10 mm |

| Pneumatic Drive: | 730 W, 6 bar (87 psi), 1400 l/mn (49 cfm) - Pneumatic driven machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Electric Drive: | 1050W, 230V or 110V |

| Optional Kit: | Automatic Clamping, Automatic Feed, Flange Facing Attachment, Tube Bevelling and Membrane Removal Kits. |

| Machining Capicity: | 32mm ID – 114.3 mm OD - With Optional Kit: 30mm ID – 355mm OD |

| Bevel Shapes & Angles: | I, V, U, X, Compound Bevels, Other Shapes on Request |

| Clamping: | Manual with Key |

| Feed Stroke: | 9 mm |

| Pneumatic Drive: | 730 W, 6 bar (87 psi), 1400 l/mn (49 cfm) - Pneumatic driven machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Electric Drive: | 1050W, 230V or 110V |

| Machining Capicity: | 43mm ID – 219mm OD - With Optional Kit: 43mm ID – 400mm OD |

| Bevel Shapes & Angles: | I, V, U, X, Compound Bevels, Other Shapes on Request |

| Clamping: | Manual with Key |

| Feed Stroke: | 16 mm |

| Pneumatic Drive: | 730 W, 6 bar (87 psi), 1400 l/mn (49 cfm) - Pneumatic driven machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Electric Drive: | 1050W, 230V or 110V |

| Machining Capicity: | 80mm ID – 355.6mm OD - With Optional Kit: 80mm ID – 610mm OD |

| Bevel Shapes & Angles: | I, V, U, X, Compound Bevels, Other Shapes on Request |

| Clamping: | Manual with Key |

| Feed Stroke: | 25 mm |

| Drive Power: | NB: Pneumatic Driven Machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Single Pneumatic Drive: | 1,47 kW, 6 bar (87 psi), 1800 l/min (63 cfm) |

| Dual Pneumatic Drive: | 2 x 1,47 kW, 6 bar (87 psi), 2 x 1800 l/min (2 X 63 cfm) |

| Electric Drive: | 2200W |

| Machining Capicity: | 150mm ID – 508mm OD - With Optional Kit: 150mm ID – 900mm OD |

| Bevel Shapes & Angles: | I, V, U, X, Compound Bevels, Other Shapes on Request |

| Clamping Capacity: | 150mm - 508mm ID |

| Feed Stroke: | 30 mm |

| Drive Power: | NB: Pneumatic Driven Machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Single Pneumatic Drive: | 1,47 kW, 6 bar (87 psi), 1800 l/min (63 cfm) |

| Dual Pneumatic Drive: | 2 x 1,47 kW, 6 bar (87 psi), 2 x 1800 l/min (2 X 63 cfm) |

| Electric Drive: | 2200W |

| Machining Capicity: | 457mm ID – 914mm OD - With Optional Kit: 457mm ID – 1828.8mm OD |

| Bevel Shapes & Angles: | I, V, U, X, Compound Bevels, Other Shapes on Request |

| Clamping Capacity: | 420mm - 920mm ID |

| Feed Stroke: | 52 mm |

| Drive Power: | NB: Pneumatic Driven Machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Dual Pneumatic Drive: | 2 x 2.3 kW, 6 bar (87 psi), 2 x 3100 l/min (2 X 109 cfm) |

| Hydraulic Drive: | 2 x Hydraulic Drives (recommended HPP: 22 kW) |

| Machining Capicity: | 600mm ID – 1000mm OD - 1000mm ID – 1500mm OD |

| Tool Feed: | Adjustable |

| Clamping Capacity: | 545mm ID – 1000mm OD - 1000mm ID – 1500mm OD |

| Drive Power: | Hydraulic Drive |

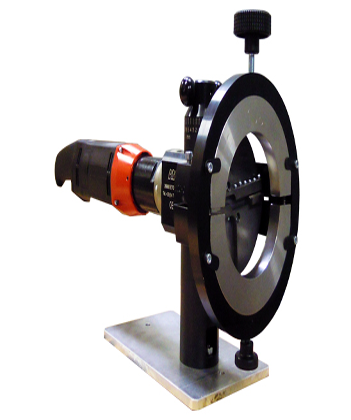

| Machining Capicity: | 18 mm (0.709”) ID - 42 mm (1.654”) OD |

| Bevel Shapes & Angles: | I, V, U, X, compound bevels, others on request |

| Clamping: | Manual |

| Pneumatic Drive : | 370 W, 6 bar (87 psi), 350 l/min (12 cfm) |

| Machining Capicity: | 10.3 mm OD – 219 mm OD |

| Bevel Shapes & Angles: | I, V, U, X, compound bevels, others on request |

| Clamping: | Manual |

| Pneumatic Drive : | 730 W, 6 bar (87 psi), 1400 l/min (49 cfm). |

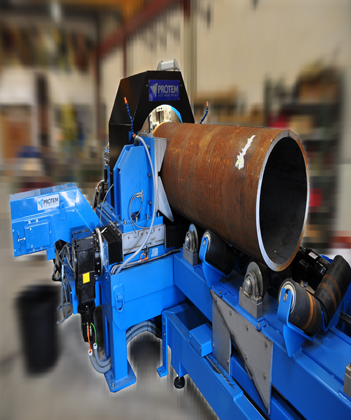

| PFM-414 HSB-80/150 |

PFM-1222 HSB-220 |

PFM-1030 HSB-420 |

PFM-3038 HSB-620 |

PFM-3848 HSB-820 |

|

|---|---|---|---|---|---|

| Pipe size range | 4” to 14” 102 to 356mm |

12” to 22” 305 to 559mm |

10” to 30” 254 to 762mm |

30” to 38” 762 to 966mm |

38” to 48” 966 to 1220 mm |

| Bevel | x | x | x | x | x |

| Face | x | x | x | x | x |

| Tool blocks fixed | x | x | x | x | x |

| Tracking carriage | x | x | x | x | x |

| Hydraulic power | HPU55kW HPP500 | HPU55kW HPP500 | HPU75kW HPP750 | HPU75kW HPP750 | HPU75kW HPP750 |

| Weight | 450 kg/ 992.1 LB | 450 kg/ 992.1 LB | 450 kg/ 992.1 LB | 450 kg/ 992.1 LB | 4000 kg/ 8818.5 LB |

| CTA 1-4 | CTA 2-12 | CTA 6-16 | CTA 12-24 | CTA 16-30 | CTA 24-36 | |

|---|---|---|---|---|---|---|

| Clamping range | 1” to 4” 25.4 to 114mm |

2” to 12” 60.3 to 323.9mm |

6” to 16” 168.3 to 406.4mm |

12” to 24” 323.9 to 610mm |

16” to 30” 406.4 to 762mm |

24” to 36” 610 to 914.4mm |

| Machining capacity | .6“ - 15mm | .6“ - 15mm | 1“ - 25.4mm | .6“ - 15mm | 1“ - 25.4mm | 1“ - 25.4mm |

| Clamping operation | Automatic | Automatic | Automatic | Automatic | Automatic | Automatic |

| Machining time | 1 to 3 minutes | 1 to 3 minutes | 1 to 3 minutes | 1 to 3 minutes | 1 to 3 minutes | 1 to 3 minutes |

| Motor power | 30 kW | 30 kW | 55 kW | 30 kW | 55 kW | 55 kW |

| Machining | Carbide insert | Carbide insert | Carbide insert | Carbide insert | Carbide insert | Carbide insert |

| Weight | ˜ 1500 Kg/3306.9 LB | ˜ 2500 Kg/5511.6 LB | ˜ 4500 Kg/9921 LB | ˜ 5300 Kg/11684.5 LB | ˜ 6500 Kg/14330 LB | ˜ 7000 Kg/15432LB |

| BB 1-6 | BB 3-16 | BB 12-24 | BB 24-36 | BB 36-48 | |

|---|---|---|---|---|---|

| Clamping range | 1” to 6” 25.4 to 152.4mm |

3” to 16” 89 to 406mm |

12” to 24” 304 to 609mm |

24” to 36” 609 to 914mm |

36” to 48” 914 to 1219 mm |

| Machining capacity | 1“ - 25.4mm | 1“ - 25.4mm | 1.37“ - 35mm | 1.37“ - 35mm | 1.37“ - 35mm |

| Clamping Process | Manual/Semi-Automatic/Automatic | Manual/Semi-Automatic/Automatic | Manual/Semi-Automatic/Automatic | Manual/Semi-Automatic/Automatic | Manual/Semi-Automatic/Automatic |

| Feed operation | Manual/Automatic | Manual/Automatic | Manual/Automatic | Manual/Automatic | Manual/Automatic |

| Machining time | Within a few seconds | Within a few seconds | Within a few seconds | Within a few seconds | Within a few seconds |

| Motor power | 30 kW | 30 kW | 37 kW | 50 kW | 50 kW |

| Machining | Carbide insert | Carbide insert | Carbide insert | Carbide insert | Carbide insert |

| Weight | 2500 Kg/5512 LB | 3500 Kg/7716 LB | 8800 Kg/19401 LB | 10500 Kg/23149 LB | 12500 Kg/ 27558 LB |

| Machining Capicity: | 8mm ID – 32mm OD - (0.315”) ID – (1.260”) OD |

| Bevel shapes & angles: | I, V, U, X, compound bevels, other shapes on request |

| Clamping Capacity: | Manual, without key |

| Drive Power: | Pneumatic Drive 370 W, 6 bar (87 psi), 350 l/min (12 cfm) - Pneumatic driven machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| Machining Capicity: | 18mm ID – 42mm OD - (0.315”) ID – (1.260”) OD - With Optional Kit 14mm ID – 42mm OD |

| Bevel shapes & angles: | I, V, U, X, compound bevels, other shapes on request |

| Clamping Capacity: | Manual, without key |

| Drive Power: | Pneumatic Drive 370 W, 6 bar (87 psi), 350 l/min (12 cfm) - Pneumatic driven machines have to be used with a lubricating filter. Recommended Option: Regulation Valve. |

| SE 25 | SE 65 | SE 2-T | |

|---|---|---|---|

| Machining | OD 2mm ID – 25.4mm-(0.07")– (1") | OD 12.7mm – 60.3mm-(0.5") – (2.37") | OD 2mm – 60.3mm-(0.07") – 2.37") |

| SL 30 | SL 60 | SL 120 | |

|---|---|---|---|

| Machining | OD 1mm ID – 30mm-(0.118")– (1.181") | OD 10mm – 63.5mm-(0.393") – (2.5") | OD 50mm – 120mm-(1.97") – 4.724") |

Kennet Equipment Leasing has been providing UK businesses with equipment finance since 1991. With access to many of the top lenders, as well as our own significant resources, we successfully place finance agreements for a huge range of businesses, of all types and sizes.

Having financed equipment to a value in excess of £500M you can be rest assured that Kennet are the people to talk to for any business equipment requirement. From £250 upwards, we will have a solution that suits your cash flow and budget.

Whether you are looking to buy equipment for your own business, or seeking an affordable finance solution for your customers, Kennet Equipment Leasing will give any business the power to grow.

Richard Nelson

Senior Account Manager

Email here

Direct Tel: 01675 469233

Mobile: 07540 952358

www.kennet-leasing.co.uk

LBW Machines now offers seven days a week, support call helpline, and call out service. This commitment ensures our clients are always operationally functional and prevents on downtime costs and issues.